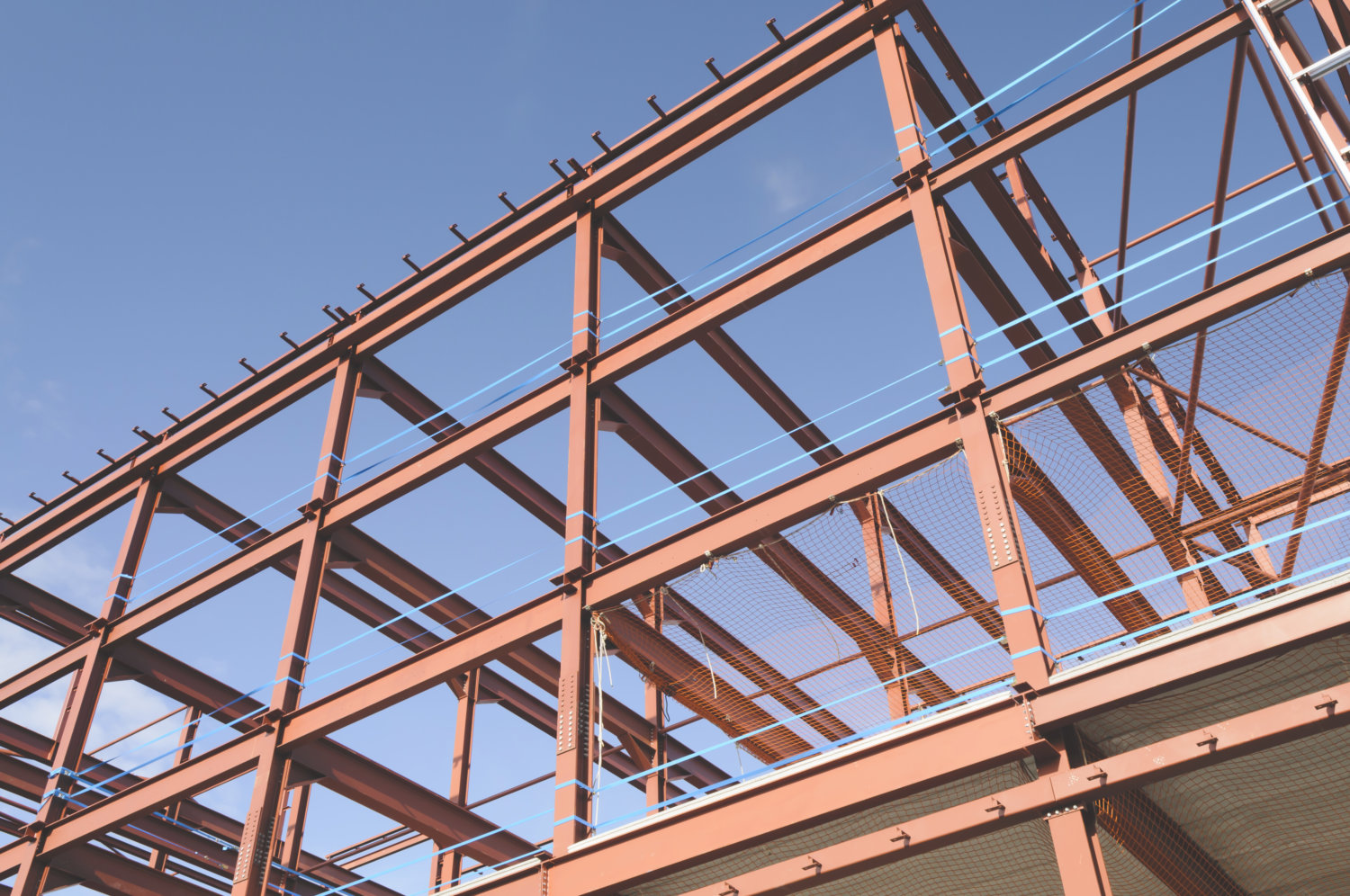

Turnkey Construction & Renovation Services

ACS provides comprehensive services for general construction and renovation, as well as civil and marine construction.

High

Quality

Our experience and commitment to our craft and our clients ensures delivery of the highest quality construction solutions.

Safety

First

We prioritize safety, from the executive level down to the men and women working in the field. Through these efforts, we have earned an excellent 0.57 EMR rating.

Renewable

We understand the impact structures and facilities have on our communities. Virtually every project ACS undertakes today has a specific target for sustainability.

Our Services

As a small business wholly owned by an Alaska Native Corporation, ACS is your strategic partner for comprehensive facility renovation and complex electrical and heavy highway construction services. Our teams are engaged throughout the Mid-Atlantic region supporting a wide variety of federal, state, local, and commercial clients.

General Construction & Renovation

- Facility Interior Renovations

- Facility Exterior Renovations

- MEP Improvements

- Communication Installations and Improvements

- Data Center Installations and Improvements

- Incidental Civil (Demolition, Foundations, Roofing, Structural Steel, Concrete, Framing, Masonry)

- Incidental Architectural Finishes (Painting, Flooring, Tile and Terrazzo, Drywall, Glass, and Glazing)

- Site Preparations

- Incidental Architectural and Engineering Services

Civil & Marine Construction

- Shoreline Restoration

- Minor Structures

- Docks / Piers

- Dredging

- Material Transportation and Disposal

Transportation Systems

- Electrical Installations

- Intelligent Traffic Systems

- Traffic Signals

- Lighting

- Sign Structures

- Fiber Optics

- Incidental Civil Construction

Company Information

codes & numbers

- UEI Number: X736E9CU5AA4

- DUNS Number: 131061181

- CAGE Code: 3LGV3

- Primary NAICS: 562910 – Remediation Services

For additional NAICS codes, please visit https://sam.gov

Featured Opportunities

You can look around, but you won’t find another company like us. Come join us!

- Competitive Benefits Package

- Diverse Workforce

- Professional Development

Contact Information

Leadership

Shannon Carney

General Manager

Karon Gilmore

Senior Director of Operations

Offices

10807 New Allegiance Drive

Suite 350

Colorado Springs, CO 80921

2553 Dulles View Drive

Suite 700

Herndon, VA 20171

Equal Opportunity Employer

We are committed to Equal Employment Opportunity and providing reasonable accommodations to applicants with physical and/or mental disabilities.

If you have a physical and/or mental disability and are interested in applying for employment and need special accommodations to use our website to apply for a position please contact Recruiting Services at:

Employment Verification

Employment verification is handled by The Work Number. Please click the link below and use the employer code 19221.

Business Ethics

In instances where you believe violations of policies or standards have occurred, please contact us using the ethics hotline.